Siraj Muhammad Funtua

Introduction

This article provides guidance on how to approach and manage the Hazard Analysis Critical Control Point (HACCP) assessment process. However, although the use of a checklist in assessing HACCP was recommended, no standard assessment data collection tool was proposed (Wallace, 2009). Several publications have also described the roles and approaches taken by government agencies in different parts of the world in the assessment of HACCP (Gagnon, McEachern, and Bray, 2000; Kvenberg et al., 2000; Merican, 2000; Torres, 2000).

Furthermore, Gagnon et al. (2000) submitted that in Canada the Food Safety Enhancement Program (FSEP) is voluntary for establishments registered under the Meat Inspection Act (MIA), and the Quality Management Programme (QMP) is mandatory for registered fish processors at the level of the Federal Government. Both of these initiatives are compatible with Codex HACCP requirements and use similar methods for verification of compliance and adequacy, including the use of critical, major and minor non-conformity ratings. Kvenberg et al. (2000) described the development of HACCP and regulatory assessment in the USA, including the FDA and USDA HACCP inspection / verification programs.

In Nigeria, food safety issues are yet to be given the needed attention; although efforts have been advanced by the Federal Government, e.g. in July 2011 the National Food Safety Management Committee was sworn in and and charged it with the responsibility for food safety and quality control measures as well as the management of the process of ensuring food safety from farm to fork (Ikhilea, 2014). Also, the Food Safety and Applied Nutrition (FSAN) Directorate of the National Agency for Food and Drug Administration and Control (NAFDAC) was established in 2013. Knowing that NAFDAC is a Nigerian Federal Agency under the Federal Ministry of Health; it is responsible for the regulating and controlling the manufacture, importation, exportation, advertisement, distribution, sale and use of chemicals, cosmetics, drugs, foods, medical devices and potable water; it should not be saddled with additional responsibilities because as for now it cannot efficiently manage its own responsibilities due to numerous challenges facing the agency. It is imperative that a separate agency that will be responsible for the safety of the domestically produced and imported foods is established in Nigeria. Professionals must be engaged in the management of this much needed agency because countries where a Food Safety Management System (FSMS) is gaining ground and successful is because the right personnel are employed for the right job.

Although regulators and food processors have the same goal of safe food / beverage production, they may have different perspectives on how to measure HACCP 'effectiveness' (Wallace, 2009). Therefore, objective and direct measures that have a baseline against which an assessment can be made and / or a change can be calculated need to be developed (Kvenberg et al. 2000). A number of other studies from several authors including Ababouch (2000), Merican (2000) and Torres (2000) have employed frameworks that include checklists and guidance for auditors. However, there is limited consistency and no globally agreed approach. For any assessment program to generate useful information, criteria to evaluate the effectiveness of the HACCP Plan and its application need to be established and assessment methods need to be clearly identified.

Building on the recommendations of Mortimore and Wallace (1998) and the International Life Sciences Institute (ILSI 1999), broad criteria for HACCP effectiveness assessment can be established and an understanding of how these criteria are met can be used to plan the data collection requirements for HACCP effectiveness assessments (Wallace 2009).

Introduction to Hazard Analysis Critical Control Point (HACCP)

Codex Alimentarius Commission (CAC, 2003) defines HACCP as a system which identifies, evaluates, and controls hazards which are significant for food safety from farm to folk. On the other hand, hazard is a biological, chemical or physical agent in, or condition of, food with the potential to cause adverse health effects (CAC 2003, IUFoST 2011). Food safety is the assurance, from the food producer / manufacturer, that a food / beverage will not cause harm to the consumer when it is prepared and / or eaten / drank according to its intended use (CAC 2003). This implies that there is a need for an effective HACCP system to be put in place that would meet food safety requirements and protect the consumer from harm that could result from either chemical, microbiological or physical hazards (CAC 2003, Wallace 2009; IUFoST 2011). This requires that the HACCP plan is both valid and fully implemented (Wallace 2009). And valid implies that HACCP will, by design, be effective in controlling all relevant food safety hazards, and fully implemented in practice could mean that the laid down requirements of the HACCP plan can be verified to be working as anticipated in the operation of food and beverage production (Wallace 2009).

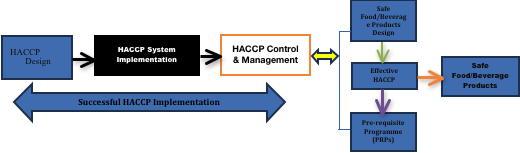

In addition to the above elaboration, food safety depends on the 'building blocks' of safe product design, prerequisite programs (PRPs) and HACCP all being applied fully and correctly (Wallace, Powell and Holyoak, 2005). Wallace (2009) is of the opinion that with respect to HACCP, achievement of effectiveness depends on the design, implementation, control and management of the HACCP system; and this framework for effective HACCP should achieve safe food/beverage production when accompanied by the other effective building blocks within the food/beverage operation (Figure I) (Wallace, 2009). However, there is a need to understand the factors impacting successful HACCP application such that food/beverage production companies can design, implement and manage systems that will control all relevant food/beverage safety hazards (Wallace, 2009).

Figure. I: HACCP effectiveness framework

Figure I demonstrate the stages in the design of a HACCP system, beginning from the HACCP design stage, implementation and management / control supported by functional PRPs, to ensure the successful production of safe foods and beverages for the ultimate consumers.

Criteria for HACCP Effectiveness

According to Wallace (2009), for a HACCP Plan to be effective, certain criteria must be met. These criteria includes: (i) assessment planning for control of significant food / beverage hazards, (ii) validity of the HACCP Plan depending on the safety hazards that are likely to occur, (iii) knowledge and operational skills of the HACCP team, (iv) studying the likely occurrence of hazards and their potential severity, and (v) ability to understand and apply the Codex HACCP principles to develop an effective HACCP Plan for implementation in everyday factory production activities. This can be achieved through a handover process from operation of the food company to the HACCP team to operations’ management and line personnel, where it is important that operations personnel take ownership for day-to-day operation of the HACCP Plan (Wallace, 2009).

In addition to the above listed criteria, implementation of HACCP plan is demonstrated through monitoring of critical control points (CCPs), taking corrective action(s) where necessary and keeping records adequately verified and maintained. Verification includes audit of the working HACCP system for compliance with the HACCP Plan and review of food safety records. Well emphasised in the same report was that maintenance involves ongoing update procedures both to evaluate the impact of changes in the operation and keep up to date on knowledge of food safety hazards (Wallace, 2009).

Therefore, in order to fully understand HACCP effectiveness, it is necessary to establish what is going on, or in other words what is happening at manufacturing sites as they work through the development, implementation and maintenance of HACCP systems (Wallace 2009). This requires a deeper understanding of the processes at individual manufacturing sites and necessitates a case study approach to evaluate how a range of potential impact factors relate to HACCP at those sites, be it either for food and / or beverage production (Wallace 2009).

Wallace (2009) also reported that it was postulated that factors involved in the success or failure of HACCP are likely to fall into three (3) main groupings: (i) personnel factors, (ii) operational management factors, and (iii) environmental factors, respectively. Hence HACCP success in each of these three (3) areas within a multinational food / beverage business should include:

· personnel Factors;

· training and fnowledge;

· HACCP team decision-making and team interactions;

· environmental factors;

· national culture;

· external pressure for HACCP;

· operational management factors;

· commitment; and

· resources and support;

HACCP Assessment

Several assessments are considered to be essential as soon as a HACCP system has been implemented by the factory, including internal assessments carried out by the food and beverage industry and independent assessments carried out by regulators and third-party organisations (World Health Organization (WHO), 1995; Sperber, 1998).

A WHO Consultation in Geneva considered the role of government agencies in assessing HACCP (WHO, 1998) and provided guidance on:

· government roles and responsibilities;

· principal activities for regulatory assessment;

· organisation and planning of assessments;

· ahe assessment process and its implementation;

· Assessor competencies, and

· specific problems encountered in assessing HACCP systems.

Conclusions

In conclusion, an effective HACCP is a system that would meet food safety needs and protect ultimate consumers of foods and beverages from harm such as foodborne illness. This is because legally people have the right to expect the food they eat to be safe and suitable for consumption and use. Foodborne illness and injury are at best unpleasant; at worst, they can be disastrous. But there are also other consequences, for instance outbreaks can damage international food / beverage trade and tourism, and also can lead to loss of earnings, unemployment and legal action against the food / beverage manufacturers.

The question for the Millennium is: In Nigeria, what is the appropriate level of HACCP application and its regulatory assessment by the industries and agencies of the government controlling the production of regulated foods / beverages?

Recommendations

Recommendations to ensure the production of safe food and beverages are as follows:

· There is the need for Nigeria, as a nation, to establish an independent Food Safety Agency of Nigeria (FSAN).

· All 36 states including the Federal Capital Territory should have an autonomous Food Safety Agency.

· All 774 local Government areas from the 36 states in Nigeria should have a Food Safety Agency Monitoring Unit that will assess the services of food / beverages at the grass-root level.

· All food production and distribution industries should be certified and recertified at least every 3-5 years of operation to ensure strict monitoring of food / beverage services in Nigeria.

· The services of experts and competent persons in the field of food safety and quality management should be employed by the Government to ensure effective professional engagement in the monitoring of food safety and quality management in Nigeria.

· The awaiting Bill for the establishment of the Nigerian Council of Food Science and Technology (NCFST) should be passed by the National Assembly as soon as possible.

· Nigeria should borrow a leaf from nations such as Canada, China, Japan, United Kingdom, and the United States of America, where food safety and management issues are given serious and needed attention.

References

Ababouch, L. (2000) The Role of Government Agencies in Assessing HACCP. Food Control 11(2): 137-142.

Codex Alimentarius Commission (2003) General Principles of Food Hygiene. CAC/RCP 1-1969. Pp 1-31.

Gagnon, B, McEachern, V and Bray, S (2000) The Role of the Canadian Government Agency in Assessing HACCP. Food Control 11(5): 359-364.

Ikhilea, MFO (2014) NAFDAC’s Drive for National Food Safety. The Nation News Paper (E-Copy) Published on the 25 February, 2014.

International Life Sciences Institute (1999) Validation and Verification of HACCP, ILSI Europe, Belgium.

International Union of Food Science and Technology (2011) Chemical Hazards in Food. IUFoST Scientific Information Bulletin (SIB). Available from http://www.iufost.org/iufost-scientific-information-bulletins-sib. Accessed 23/10/2013.

Kvenberg, J, Stolfa, P, Stringfellow, D, and Spencer Garrett E. (2000) HACCP Development and Regulatory Assessment in the United States of America', Food Control 11(5): 387-401.

Merican, Z. (2000) The Role of Government Agencies in Assessing HACCP – the Malaysian procedure. Food Control 11(5):371-372.

Mortimore, SE and Wallace, CA (1998) HACCP: a practical approach, (2nd Ed.), Gaithersburg, Aspen Publishers Inc.

Sperber, W. H. (1998): Auditing and verification of food safety and HACCP. Food

Control, 9(2-3):157-162.

Torres, DH (2000) Role of Government in HACCP Audit: a Cuban Perspective. Food Control 11(5): 365-369.

Wallace, CA, Powell, SC and Holyoak, L (2005) Development of Methods for Standardised HACCP Assessment. British Food J. 107(10): 723-742.

Wallace, CA (2009) The Impact of Personnel, Training, Culture and Organizational Factors on Application of the HACCP System for Food Safety Management in a Multinational Organisation. A Thesis submitted in partial fulfillment for the requirements of the degree of Doctor of Philosophy at the University of Central Lancashire, Preston, UK.

World Health Organisztion (1995): Training Aspects of the Hazard Analysis Critical Control Point System (HACCP). WHO/FNU/FOS/96.3, Geneva.

World Health Organization (1998) Guidance on Regulatory Assessment of HACCP. WHO/FSF/FOS/98.5, Geneva.

Siraj Muhammad Funtua MNIFST is with the Department of Food Science and Technology, Federal Polytechnic, PMB 1012, Kaura-Namoda, Zamfara State, Nigeria; Email: smfuntua@gmail.com

IUFoST Scientific Information Bulletin (SIB)

FOOD FRAUD PREVENTION