Don Mercer

Hurdles are something we frequently associate with track and field events. Unfortunately, we may also face them in our daily lives as a series of never-ending obstacles that tend to get in the way of our progress.

In food processing and preservation, hurdle technology is an approach that enhances safety by helping to impede the growth of microorganisms which can cause food-borne illnesses or promote spoilage. It involves incorporating barriers to microbial growth into the composition of the product itself, or into one or more of the processing steps.

The application of heat is one of the most common and effective methods of reducing the initial microbial population in food products. Any of you who have canned fruit or vegetables have experienced doing this by heating the food to a specific temperature, and holding it there for a prescribed period of time.

Most problematic microorganisms tend not to grow well in an acidic environment. Fortunately for us, many of the foods we eat are somewhat acidic in nature. By adding lemon juice, or even cider vinegar, we can increase their acidity to the point where the proliferation of these troublesome microbes is substantially reduced or halted completely.

Water is a major factor in supporting microbial growth. If moisture is removed, spoilage can be significantly reduced. Drying is an obvious way to remove moisture, but water can also be made unavailable by chemically binding it with salt or sugar. This is the basis of intermediate moisture foods, or “soft-moist foods”, as they are often called.

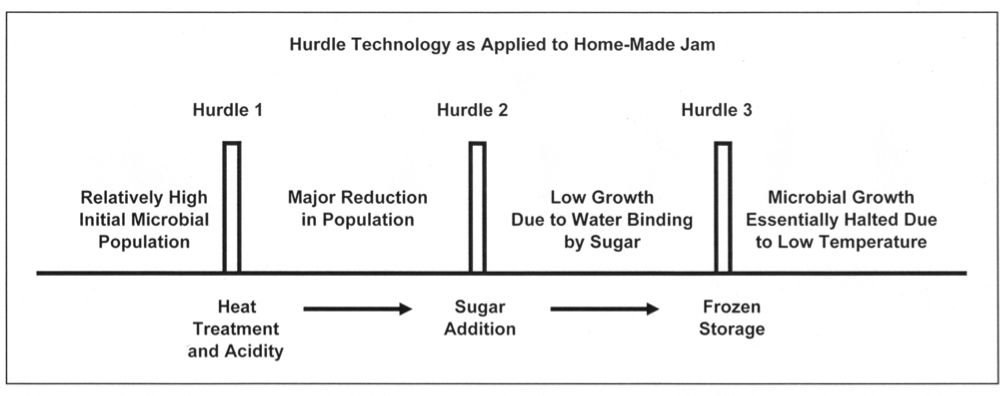

Let’s take a look at how we can use hurdle technology in preparing a favourite food in many homes – strawberry jam. A simple diagram will help illustrate the hurdles we are incorporating into the jam.

Jam-making usually involves preparing the raw fruit and blending it with a sugar while heating the mixture on the stove. Most of the microorganisms that were present after the fruit was washed will be destroyed during this heating process. The addition of lemon juice (or lemon juice concentrate) increases the acidity of the mixture. This not only creates a less favourable environment for the remaining microorganisms to grow, but also helps the pectin in setting up a gel structure when it is added towards the end of the heating step. Even though the sugar might appear to be simply increasing the sweetness of the jam, its primary function is to bind the water that is present, and thereby make it unavailable for microbial growth.

The hot jam can then be poured into clean glass jars which should be tightly sealed to prevent air-borne contaminants from entering and contacting the contents of the jars. As it cools, any air at the top of the jars contracts in volume and creates a slight vacuum. We see this by the concave curvature of the metal lid on the jar, and we may hear the “pop” when we open the jar later. The lack of oxygen inside the jar could also be considered as a hurdle to some microorganisms that require it to grow. This hurdle has not been included in the diagram.

Some people like to make “freezer jam” which has no heating step. It relies on freezing the product to minimize any microbial growth. At our house, we prefer the taste and smoothness of cooked jam over freezer jam. However, being rather cautious “belt and suspender” types, we freeze our cooked jam and add this major hurdle to the existing arsenal of preservation techniques. In over thirty years of doing this, we have not had any problems with spoilage.

The bottom line in any activities involving food preservation and storage is to follow the guidelines set by reliable, trusted sources. Do not take any shortcuts - and above all, do not modify any procedures or recipes. Strict adherence to details, and maintaining a high level of cleanliness will go a long way in providing safe, high quality home preserves.

Dr Don Mercer is Associate Professor in Food Science, Department of Food Science, University of Guelph, Guelph, Ontario N1G 2W1, Canada; e-mail: dmercer@uoguelph.ca

Permission to reproduce this article is greatly appreciated and acknowledged.

IUFoST Scientific Information Bulletin (SIB)

FOOD FRAUD PREVENTION