Alastair Hicks

Makerere University

Introduction

Food production is the most important economic activity in Africa and many other developing countries. However, the food production sector is faced with the challenge of high postharvest losses (estimated at 20-25% for root and tubers, 5-15% for cereals and legumes, and >35% for fruit and vegetables in East Africa), poor quality of food supply, limited value addition, limited product diversity, low farm gate prices. There are currently limited interventions in East and Horn of Africa region promoting food processing and proper postharvest practices.

As a step towards mobilisation of key stakeholders engaged in postharvest and processing research and interventions, a workshop was conducted. The workshop was organised by Makerere University, School of Food Technology, Nutrition & Bioengineering, with funding from the McKnight Foundation. The aim of the workshop was to engage researchers, development workers, policy makers and agricultural practitioners to develop a model for utilisation of agro-processing and postharvest technologies to improve nutrition, food security, livelihoods and sustainability.

To achieve this, a regional multi-stakeholder three day workshop was conducted under the leadership of Professor John H. Myongi, Dean, Faculty of Agroindustry, Makerere University, Uganda, with sponsorship by the McKnight Foundation, USA.

Objectives

The objectives of the workshop were to:

share experiences on the potential role of agro-processing and postharvest technologies in the improvement of nutrition, food security, livelihoods and

* Summary by Alastair Hicks of full Workshop report sustainability for resource constrained agricultural communities;

assess prospects for utilising agro-processing and postharvest technologies for improvement of nutrition, food security, livelihoods and sustainability for resource constrained agricultural communities in East and Horn of Africa region (E/HAf);

develop a strategy for wider, effective, sustainable application of regionally adaptable postharvest and agro-processing technologies and interventions for food security, livelihoods in E/HAf; and

collectively design interventions for utilisation of agro-processing and postharvest technologies, for improvement of food security, nutrition, livelihoods and sustainability for resource constrained agricultural communities in E/HAf.

Outputs

The expected immediate results of the workshop were:

a clearer appreciation of the potential contribution of agro-processing and postharvest technologies to improvement in nutrition, food safety, food security, livelihoods and sustainability; and

a plan of action for application of agro-processing and postharvest technologies in E/HAf.

Rationale of Activity

Most projects under the CCRP East and Horn of Africa Community of Practice (CoP) focus on increasing agricultural production to improve nutrition, food security, livelihoods and sustainability. Several projects have project components related to food processing, but these aspects have yet to be given concerted attention by the CoP. Given the high postharvest losses, poor quality of food products and the low value of farm produce, adoption of appropriate agro-processing and postharvest technologies has potential to leverage these investments in increased production. A regional workshop was considered an appropriate forum for designing regionally adaptable interventions that promote appropriate agro-processing and postharvest technologies.

Workshop Implementation

The workshop was attended by 40 participants from E/Haf and sister Communities of Practice. Participants included scientists working on Collaborative Crop Research Program (CCRP)-funded projects, also non-governmental organisations implementing community development (CCRP) project activities in the region, government agriculture department representatives, representatives from McKnight Foundation, CCRP regional team and Dr Alastair Hicks, an international expert with global experience in implementing community based agro-processing projects.

The workshop took place in Entebbe, Uganda from 3-5 April 2013. The workshop entailed background presentations for the first day and general discussion during the second and third days. The titles for the background presentations are listed below:

McKnight Foundation’s Collaborative Crop Research Program;

Background and workshop objectives;

Food Processing as a tool for rural development: Global examples;

Postharvest losses in E/HAf: Current status and opportunities for reduction;

Experiences of promoting community level food processing in Kenya;

Sasakawa’s experiences in promoting community postharvest technologies ;

Experiences in promoting agro-processing of grain amaranth;

Impact of seasonality on food security and potential for mitigation through food processing and postharvest technologies: Case of Uganda;

Impact of seasonality on food security and potential for mitigation through food processing and postharvest technologies: Case of Ethiopia;

Potential contribution of agro-processing and postharvest technologies to socio-economic development in East and Horn of Africa Region; and

Social considerations to enhance benefit of postharvest and agro-processing interventions.

Key Messages from Workshop Deliberations

Potential Benefits of Adopting Appropriate Postharvest Handling and Agro-processing Technologies

Potential benefits include:

enhancing nutritional value of processed foods;

enhancing value to producers, marketers and processors;

increasing food availability, processing raw materials into diverse products;

reducing postharvest losses of agricultural products and foods;

improving food product safety and quality;

reducing drudgery during handling and preparation of foods;

facilitating spatial and temporal distribution of agricultural produce;

improving acceptability of processed foods;

reducing bulk of food products for transport to market; and

diversification of household income sources by agro-processing.

Constraints to Wide Applications of Postharvest Handling and Agro-processing Technologies

Constraints include:

inadequate human capacity in postharvest handling / processing technologies;

limited access to appropriate technology at community level, postharvest handling and processing;

limited options, high cost of packaging for acceptable, competitive food products;

weak business linkages between producers, suppliers and the market hamper development of agro-processing;

low volumes of farm outputs do not encourage agro-processing;

seasonal production of raw material is a challenge to agro-processing;

unsupportive culture lacks focus on value addition and entrepreneurship;

high start-up needs for postharvest, agro-processing equipment / infrastructure; and

under-developed markets for processed foods need promotion.

Proposed Interventions to Promote Postharvest Handling and Agro-processing Technologies

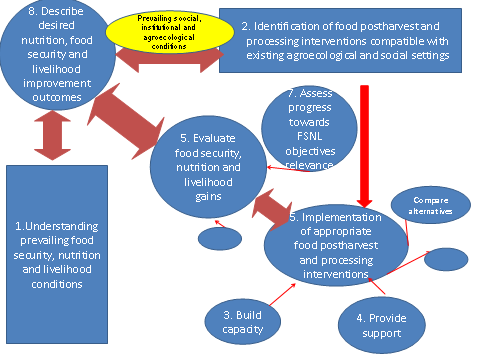

Regardless of the specific postharvest and agro-processing interventions to be promoted, it is important to set clear targets and to choose technologies that are amenable to the existing biophysical and socio-cultural conditions. It is also important that the intervention is continuously monitored and where necessary adjusted to ensure that it addresses the prevailing circumstances.

Figure 1 provides a generic model that could be adopted in planning of post harvest and agro-processing projects aimed at addressing community food security, nutrition and livelihood improvement.

Identified specific interventions include:

human capacity building to engage in postharvest and processing training and skills development;

development of appropriate processing equipment useable by women on locally available foods;

development of formulations suitable for feeding nutritionally vulnerable groups;

improving knowledge about and access to available food packaging options;

building and strengthening business linkages providing financial services, market information, marketing and distribution support;

raising critical volume of agricultural produce for processing, through cooperative efforts;

stabilisation of seasonal supply through semi-processing and storage;

promoting a culture of agro-processing and consumption of processed products; and

establishment and support of agro-processing co-operatives / groups.

Establishment of communal produce handling and processing facilities would go a long way in promoting community level agro-processing. This will need to be coupled with institutional development for community-based agro-processing groups. The above could be undertaken by development and government agencies and farmers’ organisations. There are also opportunities for the private sector to establish agro-processing facilities that could be utilised by community-based groups for a fee.

Conclusions and Recommendations

Wide adoption of postharvest and agro-processing technologies has the potential to contribute to improved food security, nutrition and livelihoods. There are limited current efforts aimed at promoting postharvest and agro-processing technologies in Eastern and Horn of Africa region. Intervention programs aimed at promoting community level postharvest and agro-processing are required to fill the current gap. Planners of such interventions should take cognizance of the prevailing biophysical and socio-cultural environments as well as the likely constraints. It is critical that such interventions address skills gaps, social, institutional, economic, technical and raw material access constraints.

It is also important for the interventions to ensure that postharvest and agro-processing programs do not promote financial gain at the expense of nutrition and food security. Effective implementation of postharvest and agro-processing interventions will generally require input from many stakeholders, including farmers, government, development agencies, the private sector and researchers. There is need for advocacy to raise interest in postharvest and agro-processing interventions among such stakeholders.

Participants of the Regional Workshop on Community Level Food Processing To Improve Nutrition, Food Security, Livelihoods and Sustainability, Entebbe, Uganda, April 2013 (Alastair Hicks is far left, back row)

Workshop participants in Entebbe examine upgraded traditional food products made by the School of Food Technology and Bio-Engineering, Department of Food Technology and Nutrition, Makerere University, Kampala, Uganda

The following report by Alastair Hicks is of the First FAO Regional Expert Consultation on Upgrading of Traditional Food Technologies, held in Arusha, Tanzania, 3-7 November 1986.

First FAO Regional Expert Consultation on Upgrading of Traditional Food Technologies

Arusha, Tanzania, 3-7 Nov 1986

Alastair Hicks

Background

Many traditional technologies have remained unchanged for centuries and are location specific. They are deep rooted in their natural, cultural, religious and socio-economic environment. These technologies held a fine balance between production and consumption. Given the economic and social circumstances in many developing countries, traditional food technologies do not fully meet people’s needs for food security and the prevention of food losses. This FAO Regional Expert Consultation provided a forum for experts from eight (8) African countries to discuss the upgrading of traditional food technologies, focus on specific technologies, and identify areas for future development. It was funded by the FAO Special Account of the Prevention of Food Losses Programme (PFL).

Introduction

A major issue of this 1986 Consultation was how the indigenous food supply in Africa could be improved and protected, by upgrading of traditional food processing industries. Productive employment through upgraded traditional food technologies, how these technologies combat poverty and increase income generation, among landless workers, rural women, vulnerable groups and small entrepreneurs, was discussed. A range of solutions was outlined in the papers presented at the Consultation, for upgrading traditional food technologies.

Objectives

Promote information exchange on success and shortcomings in development, and upgrading of traditional processing technologies;

Analyse traditional technologies, current or potential technical improvements, including socio-economic significance, constraints for their development;

Recommend efficient use of national, regional and international resources in prevention of food losses, based on identified upgraded technologies; and

Identify target groups, technical and management requirements, needed to modernise their small scale enterprises, to improve their incomes.

This 1986 Expert Consultation condensed report is recorded here as a benchmark, to provide a comparison and contrast to the trends and improvements reflected in the 2013 Regional Workshop reported earlier.

Participation

Sixteen (16) participants from eight (8) African countries ̶ Ethiopia, Ghana, Kenya, Nigeria, Senegal, Sierra Leone, Sudan and Tanzania ̶ and Appropriate Technology (AT), a US development assistance organisation, attended the Consultation in their personal expert capacities. Alastair Hicks, Food Industries Officer from FAO HQ Rome, was the meeting organiser, accompanied by the FAO Regional Agro-Industries Officer for Africa, and an FAO staff secretary (Italy).

1986 Participants from eight (8) African countries (Ethiopia, Ghana, Kenya, Nigeria, Senegal, Sierra Leone, Sudan and Tanzania), FAO (Italy) and Appropriate Technology (USA). Alastair Hicks is centre of the front row

Conclusions and Recommendations

These follow from the deliberations of three Working Groups (Agro-Industries, Roots and Tubers, and Cereals and Oil Seeds). Constraints and areas for development were identified.

Conclusions: Agro-Industries Group

Raw material is a limiting factor for small scale agro-industries, due to:

limited purchasing power for agricultural inputs;

land tenure difficulties;

lack of credit for seeds, fertilisers, implements, others;

lack of tools, equipment for harvesting, transport and storage of raw materials;

lack of facilities for equipment conception, manufacturing design for proper handling of agricultural products;

poor storage, inadequate postharvest techniques;

bad road infrastructure, transport, and handling facilities;

lack of price incentives and marketing policy.

Agricultural produce artisanal-level processing has serious constraints due to:

sub-standard facilities for processing;

lack of utilities and services, with irregular supply of raw materials;

unsuitable equipment for product capacity, also packaging materials;

poor quality assurance, with untrained staff and operators;

lack of outlets for commercial products;

lack of an integrated approach to production, processing and distribution;

few clear, defined Government policies on these constraints.

Distribution, marketing and utilisation of indigenous products are hampered by:

inadequate roads, transport infrastructure, causing uneven product distribution;

poor product publicity coupled with lack of market information;

limited retail opportunities and irregular supply of products to the market; and

short shelf-life, unattractive presentation and lack of product quality assurance.

The Agro-Industries Group included a representative for apiculture, and the key importance of apiculture was recognised in the development of food industries. In many West African countries, beekeeping was in its initial stages, and unsuitable methods were used. A need was seen to stimulate the beekeeping industry for the qualities of its main product honey and other by-products such as propolis, also because of the vital importance of bees in pollination of food plants.

Conclusions: Cereals/Oil Seeds Group

The Group concluded:

upgraded traditional technologies apply to the processing of sorghum / millet, maize, rice and palm oil;

some of the unit operations, e.g. milling, are technically advanced for small scale producers and need to be scaled down to the appropriate level; and

some of the improved technologies are not wide-spread nor widely known.

Conclusions: Roots and Tubers Group

The Group concluded:

the major roots and tubers in Africa are cassava, yams, sweet and Irish potatoes, and coco yam (taro);

the unit operations consist of peeling, slicing, grating, mashing, fermenting, dewatering, drying, roasting (‘garifying’), sifting, milling and packaging, in relation to the above products;

attempts have been made to upgrade some of these unit operations with a view to removing the drudgery and inefficiency of these operations;

efforts for mechanisation of peeling were disappointing;

satisfactory equipment for grating roots and tubers exists from small and medium up to large scaleh

Hot air drying is suitable at high levels of operation, but not at the village level;

applied research work has been carried out on solar drying, but these techniques have not had significant impact in terms of commercial application so far;

processing of cassava to gari - the sieving operation has been mechanised on the medium - large scale, but still has to be improved for use at village levels;

garifying has been upgraded at traditional, intermediate and advanced levels.

Recommendations – Combined Groups

Governments need to support small-scale staple food agro-industries to secure a raw material base by

guaranteeing producers access to land for secure production of raw materials;

Providing fair credit and investment opportunities, to rural farmers;

Improving access to agricultural extension, other government services, for producers of raw materials for processing;

Developing marketing support systems for the raw materials through suitable pricing policies

Disseminating market information, providing some stability for the producers;

Improving distribution and transport infrastructure;

Providing rural labour training facilities;

Supporting applied research activities for raw material development, through modern technologies.

Governments should liaise with international agencies, to improve small-scale processing, storage and marketing by:

improving capability for the design and construction of adequate haulage vehicles and equipment for harvesting, storage and processing;

identifying national focal points to foster and coordinate the upgrading of traditional foods;

supporting the formation of associations of small scale processors as advisory bodies to governments;

assisting in the establishment of Community Processing Centres, to develop training programs and workshops for small scale food processing operatives and entrepreneurs, particularly women and other vulnerable groups.

Governments, in collaboration with international organisations, should promote specific food commodities to:

improve the production, processing and utilisation of cereals and oil seeds by upgrading traditional storage / handling facilities, to reduce postharvest losses;

promote R&D for roots and tubers processing, peeling at the small-scale commercial level, also drying and mechanical sieving at the village level;

continue to develop promotion and extension material for apiculture as a small scale agro-industry;

prepare specifications for, and generate supportive regulations to raise quality of indigenous products, and also survey nutritional data for these products;

promote Technical Cooperation between developing Countries (TCDC) and their institutions on upgrading of traditional foods;

strengthen linkages between governments, R&D institutions, universities, and small scale processors;

stimulate research on traditional staple foods packaging,

transfer upgraded traditional food technologies, applying existing R&D; and

adapt modern technologies, biotechnology and genetic engineering, for example in the development of fermented staple foods.

Study Visit to Centre of Agricultural Mechanisation and Rural Technology (CAMARTEC) in Arusha

The participants studied CAMARTEC’s efforts in building materials, rural transportation, energy and water supply equipment, and food processing equipment. CAMARTEC is designing products suitable and affordable for the rural population. Of interest was a simple but efficient, low-cost prototype coffee pulping machine, developed by a farmer / artisan from a local village, who showed the operation of the machine to the participants.

Summary Report of the Consultation

The papers’ topics ranged from improved equipment to processing produce on the farm, or preparing meals in the home, to the production of “traditional” food products by medium scale processing machinery. Overall recognition was that the potential of national food industries has not yet been fully realised, and that many technical challenges face small-scale food processors.

The participants agreed that food processing at any level still requires an ample, reliable supply of raw material. A production environment is needed to helps farmers produce this supply. Income-generation by traditional food processing cannot work if processors have to compete with low-priced imported foods, poor market conditions, and a lack of supportive policies. An example was seen in newly-established food habits, formed by government subsidies in some countries, favouring wheat flour imports, and excluding indigenous flours.

Even with the strategic importance of food self-sufficiency in Africa, doubt was expressed that traditional food processing and prevention of postharvest food losses received enough attention. Frequent concerns were that small-scale food processors, and women in particular, were bypassed by development, in the political decision-making process and in terms of technological innovation. The participants strongly proposed to identify focal point persons to foster and coordinate the upgrading of traditional foods, with governments, food research institutes, and associations of food processors. At the village level, these focal points would be closely linked with Community Processing Centres that give support, and provide training facilities, for small-scale processors especially women.

This Consultation was a first regional forum for information exchange between African organisations and institutions that would foster traditional food processing. Their conclusions and recommendations were endorsed in a plenary session.

Dr Alastair Hicks (3rd from left, front row)

For 20 years, Dr. Hicks was Senior FAO Regional Officer for Agroindustries and Postharvest, with FAO/UN Regional Office for Asia and Pacific (Thailand), earlier as a Food Industries Officer with FAO/UN (Rome). He is currently an Adjunct Professor of Agroindustry at Mae Fah Luang University, Thailand, a Life Member of the Thai Food Science and Technology Association (FoSTAT), an elected Fellow of the International Academy of Food Science and Technology (IAFoST), and an elected Life Fellow of the Australian Institute of Food Science and Technology (AIFST). He maintains professional interests in international citizenship, development and education, and is an African – born Australian. E-mail: alastairhicks@gmail.com

IUFoST Scientific Information Bulletin (SIB)

FOOD FRAUD PREVENTION