Don Mercer

There is always a quest to find alternate ways to process foods. Over the past two hundred years, technology has advanced from simply heating foods and sealing them in a metal canister to using much more sophisticated methods.

High pressure processing has eliminated the need for excessive heating and destroys microorganisms present in food by disrupting their structure at the molecular level. Microwave ovens subject food to an oscillating electromagnetic field and create heat by friction from the polar water molecules rubbing together. Another rather imaginative process passes an electric current directly through the food material to heat it and destroy undesirable spoilage microorganisms which may be present.

Most of us are familiar with the basic operation of a toaster, or the heating elements in devices such as hair dryers. When an electric current is passed through a metal wire, a resistance is created and the wire heats up – often to a glowing red colour. This same principle can be applied to heating food. The process is known as “ohmic heating” since it relies on resistance, measured in ohms, to heat the food. The concept originated back in the 1840s when James Prescott Joule showed that water would heat up when an electric current was passed through it.

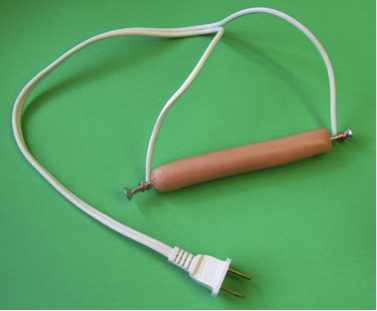

To demonstrate this concept in my classes, I use a photograph of a wiener which I wired up with a metal electrode inserted into each end. An electrical cord attached to each electrode with a plug on the other end completes this visual aid. I warn my students not to attempt using something like this due to the inherent risks involved; and I certainly don’t want anyone reading this article trying it either. However, there are now videos on the internet showing what happens when very similar devices are energised. So don’t try it at home – watch the YouTube videos instead, and play it safe.

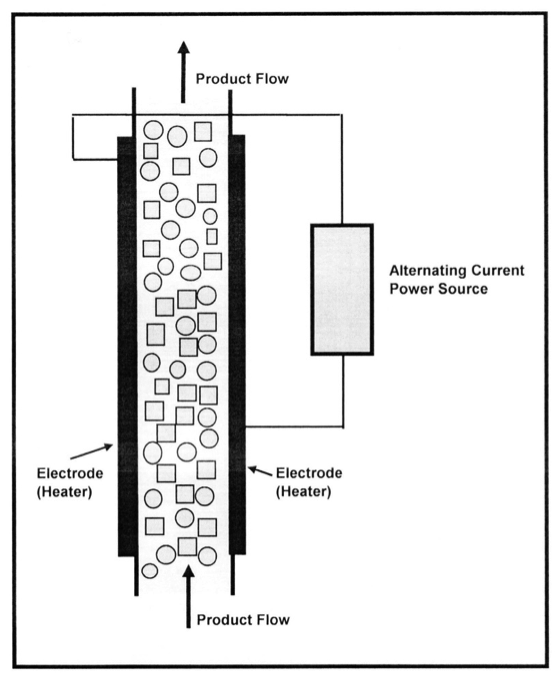

Commercial ohmic heating processes use a vertical plastic tube through which food is pumped in the upward direction. This will keep the tube flooded with product and prevent large air gaps that could result if the food was poured into the top and allowed to move downwards. The accompanying schematic diagram, which is not nearly as exciting as the electrified hotdog, may help you to visualise the process. The various shapes in the product represent solid particles that may be present in the mixture.

Diagram of a heating assembly in an ohmic heating process

Metal plates situated at intervals along opposite sides of the plastic tube act as electrodes. In order for an electric current to travel from one of these metal plates to its partner on the other side of the tube, the current must pass through the food. By using a sufficiently high voltage with the appropriate number of electrode pairs, and a suitably slow pumping speed, the process can be adjusted to heat the product to its desired final temperature. Each set of electrodes is isolated from the others due to the insulating effects of the plastic tube.

Ohmic heating eliminates variations in temperature throughout the material by a process known as “volumetric heating” which gives a more uniformly processed product than obtained from some of the other more traditional heating methods.

Ohmic heating is considered as being energy efficient and has applications for processing pumpable sauces, fruit compotes, fruit pie fillings, tortellini in tomato sauce, beef bourguignon, vegetable curry, and oriental vegetables. Although its use is not nearly as widespread as traditional heating techniques, ohmic heating is one more example of the creativity shown in food processing.

Dr Don Mercer is Associate Professor in Food Science, Department of Food Science, University of Guelph, Guelph, Ontario N1G 2W1, Canada; e-mail: dmercer@uoguelph.ca

Permission to reproduce this article is greatly appreciated and acknowledged

IUFoST Scientific Information Bulletin (SIB)

FOOD FRAUD PREVENTION