Don Mercer

For many of us, they are simply “drink boxes”. We pull them out of the refrigerator, jab the straw through the covered hole on the top, and casually throw them away when they are empty. However, there is much more to these ubiquitous containers than meets the eye.

“Drink boxes” are a form of aseptic packaging commonly used for juice-based beverages. Although the concept was developed quite a number of years ago, the 250 mL box format began its meteoric rise in popularity back in the early 1980s. Larger food companies were looking for ways to expand their presence on grocery store shelves, and aseptic drinks were an attraction they just couldn’t seem to resist. As competition increased, many of the players dropped out of the game, and the market segment began to stabilise in the mid to late 1990’s.

The aseptic principle is quite straight-forward. It consists of sealing sterile product in a sterile package while both are in a sterile environment. Equipment manufacturers use different methods of achieving this sterile environment within their aseptic packaging machines.

The beverages themselves are passed through a high-temperature-short-time (HTST) process that heats the liquid and holds it at the prescribed temperature for a given period of time. Following the heating step, the beverage is considered to be commercially sterile. Quality control tests are used to confirm that there are no microorganisms present that could create problems later. The HTST process then rapidly lowers the beverage temperature using a rather ingenious heat recovery system which reclaims heat from the commercially sterile product to warm the incoming cold raw product. Once cooled, the beverage can be held in a sterile tank which feeds the aseptic packaging machine.

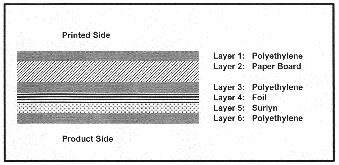

One of the more interesting things about aseptic packaging that is often overlooked is the structure of the packaging material itself. A simple diagram will help explain the six or more layers incorporated into the flexible packaging material. The critical layer from a structural point of view is the paper board which provides strength to the finished package. However, paper board on its own is completely lacking in any ability to hold a liquid product. This problem can be overcome by coating the paper board with a film of polyethylene (which is a basic “plastic”). Paper board can also become soiled on the outside and may not provide a suitable surface for printing. A layer of polyethylene on the outside easily remedies this situation.

A diagram of the layers present in a typical aseptic packaging material

Although the inside polyethylene layer can protect the paper board from the liquid, oxygen from the outside air can easily permeate through the polyethylene. Oxygen can reduce the levels of vitamin C in the juice and possibly react with delicate flavor oils to create undesirable off-notes. The solution to this problem – add a very thin layer of aluminum foil. The polyethylene layer on the paper board does double duty and serves as an adhesive to keep the aluminum foil in place. But not so fast – natural acids in citrus juices or apple juice can react with the metal foil and corrode it.

Measures must now be taken to protect the aluminum foil. Covering the foil with a layer of polyethylene won’t really work because the acidic ions can permeate through the polyethylene. Back in the 1980s, a layer of a special polymer called “surlyn” was placed over the foil to act as a barrier to these acidic ions. The “surlyn” in turn, needed to be protected from the liquid since it does not function well in contact with water. Therefore, a final layer of polyethylene was placed between the “surlyn” and the beverage.

The inside layer of polyethylene also meets regulatory requirements for sterilisation. Polyethylene is one of a select group of polymers that can be sterilised with peroxide solutions. This surface is exposed to peroxide to effectively destroy potential harmful microorganisms. Measures are then taken to remove all traces of peroxide from the packaging surface before it comes to the filling step.

Once the sterile package has been filled with sterile product, it is sealed and leaves the sterile area of the packaging machine. After receiving a production code, the “drink box” goes to a secondary packaging line where it can be bundled into multi-packs and placed in cases which are stacked on pallets for warehousing and distribution.

In addition to the six layers shown in the diagram, we might also consider the design printed in ink on the outside of the package to be an additional layer. Often, a thin coating of a lacquer is laid over the printing to protect it from abrasion and create a glossy finish. In effect, this gives the package a total of eight layers.

The next time you finish a “drink box” take a closer look before you dispose of it. Look at the way the bottom is formed, and how the seam is formed up the back of the package. You may even want to cut it open with a pair of scissors and try pulling some of the layers apart. It’s really amazing what steps are taken to protect the quality of the product.

Dr Don Mercer is Associate Professor in Food Science, Department of Food Science, University of Guelph, Guelph, Ontario N1G 2W1, Canada; e-mail: dmercer@uoguelph.ca

Permission to reproduce this article is greatly appreciated and acknowledged.

IUFoST Scientific Information Bulletin (SIB)

FOOD FRAUD PREVENTION