Inneke Victor and Valérie Orsat

Abstract

Food safety and security of indigenous food has become a matter of concern as consumers demand safe food. The local people of Indonesia consume an indigenous sugar obtained from the sap of Arenga pinnata Merr, processed as solid and granulated sugar. So far, food safety standards on processing of solid and granulated sugar have not been a concern to the local farmers. Granulated sugar has high market demand. In spite of its economic importance, most farmers refrain from processing granulated sugar as they lack the information on processing which is a potential threat to the survival of indigenous food. Adding to this, there is a huge research gap on the processing of A. pinnata sugar. A. pinnata sugar is considered to have potential health benefits according to the indigenous Indonesian society, but there is no comprehensive study on the processing parameters and nutritional analysis of this sugar. The main objectives of this study are to determine the important baseline process parameters in order to produce quality granulated sugar and to characterise the phyto nutrients present in A. pinnata sugar. Controlled boiling was chosen for the processing of the A. pinnata sugar as it is the most practical and useable method for the local community.

Keywords : A. pinnata sap, A. pinnata granulated sugar, food safety, processing, phyto nutrient

Introduction

Arenga pinnata Merr is a type of palm tree growing in tropical forests and is native to the Indo-Malayan archipelago, easily found in South and Southeast Asia (Mogea, Seibert and Smits, 1991). Among the 3000 palm species of the tropics and subtropics categorised as multipurpose trees, the A. pinnata tree is considered as one of the most diverse multipurpose tree species under culture, and the only one attracting widespread economic interest (Mogea et al. 1991). Having around 150 Indonesian local names such as arenga palm, black fibre palm, gomuti palm, aren, irok, bagot, kaong, enau, kabung, nira, saguer, and sugar palm illustrates its multipurpose interest with the local use of the sap, fruits, fibres, young leaves, steamed core, wood and roots of the tree (Mogea et al. 1991, Sahari et al. 2012). Among those uses, the sweet sap (Figure 1), which has been recognised as the strongest sugar solution of any known trees in tropical areas, is claimed to be the most important product (Mogea et al. 1991) and is usually consumed by the local people as a sweetener. Further, local people can generate income from producing sugar processed from the sap which is a common practice in Indonesia.

Fig 1. A. pinnata sap

Fig 2. Processing of A. pinnata sugar by Sugar indigenous people

Fig 3. Solid “stone/red”

Fig 4. Granulated “ant” sugar

Indigenous Knowledge of A. pinnata Sugar Processing and Associated Problems

In Tomohon, Indonesia, normally the sap is collected twice a day, in the morning when the sap is tapped during the night and in the afternoon when the tapping begins in the morning. The sap is tapped from inflorescence which must be beaten usually by using a wooden mallet for several minutes each day for about two or three weeks until the stalk itself becomes swollen. Afterwards, the stalk is cut at the swollen section to flow the sap. One tapping operation can take about 15-20 minutes (Mogea et al. 1991). The sap is collected in a container, often a bamboo pipe of 1.5 m length and a diameter of about 7 cm, which is fixed beneath the cut stalk. However, nowadays farmers also use jerry cans instead of bamboo to collect the sap. A. pinnata fibre, locally called ijuk, is used to cover the mouth of the bamboo pipe and the stalk in order to prevent contamination by outside debris.

The sap is then boiled in a round iron pan over a wood-fire. When crystallisation has started, the thickened sugar is poured into a mould which consists of a coconut shell, normally used to form solid sugar (Figure 2). This type of sugar is known locally as “stone sugar” or “red sugar” (Figure 3). Besides the produced solid sugar, granulated sugar, locally named as ‘ant sugar’ (Figure 4) can also be produced by stirring the thickened syrup of A. pinnata boiled sap until it is dried and forms granules. Considering these two type of sugars, granulated sugar has better price and market rather than solid sugar. In spite of its economic benefits, most farmers refrain from processing granulated sugar as they lack appropriate information on processing parameters, whether the sap can be processed into granulated sugar or not. There is a thought among the farmers that only farmers who have lots of experience can achieve success in the production of granulated sugar. This condition becomes worse as very few studies have been done on the processing of A. pinnata sap into sugar, although the sap is traditionally collected and has been consumed for decades as a sweetener. Further, the indigenous people believe that the sugar might have a good potential as a healthy sugar, but for which sufficient information is not already known.

Farmers as part of food producers are responsible for providing safe food to their customers. Our work on the A. pinnata sugar processing benefits the farmers and related industries to maintain the sap from deteriorating with fermentation during sap harvesting and handling, during the heating process, and therefore working at enhancing food safety. Moreover, research on indigenous foods can help efforts to protect the natural environments.

Determination of Imperative Parameters of A. pinnata Processing to Enhance Food Safety

Changes in Arenga pinnata sap

Recently, minimal sap characterisation, based on its pH, has been used by local people in Indonesia to determine the quality of the sap, whether it can be used or not in the production of granulated sugar. Sap with pH of 6-7 is considered to be of good quality for use in the production of high quality sugar (Marsigit 2005, Rindengan 2006). However, fresh sap which has a nearly neutral pH is easily spoiled as identified by a decrease of pH of the sap with time, thus the sap must be processed as soon as possible (Marsigit 2005, Rindengan 2006). Microorganisms from the environment during the collecting and transporting processes contaminate the sap easily. Marsigit (2005) cited that the yeast Saccharomyces cerevisiae is commonly found in the sap resulting in a rapid fermentation and conversion to acids.

A method commonly applied by the farmers in Tomohon to prevent sap deterioration during harvesting is the use of mangosteen rind or a piece of mangosteen tree bark which is inserted into the container installed at the tapped inflorescences. Rindengan et al. (2006) reported the use of coconut coir, a natural fibre extracted from the husk of coconuts, to keep the sap from fermenting for 3 h after the tapping process. Other additives such as candle nut and coconut oil have been reportedly used in some sugar production centres. However, these methods result in a darker sugar (Marsigit 2005, Rindengan 2006).

Changes in pH were suggested to be used as a measure of deterioration of sweet sorghum (Lingle et al. 2013), whereas using color changes as a freshness indicator of food has mostly been reported for fruits (Gonçalves et al. 2007; Łysiak 2012), fish (Yagiz et al. 2009), beef (Page, Wulf and Schwotzer 2001), and other fresh and processed food products (Pathare, Opara and Al-Said 2013).

We observed pH changes of the sap over time. Higher pH caused A. pinnata sap to appear more transparent (clearer), whereas lower pH caused the sap to appear white. The result supports the hypothesis that colour is also a good indicator of quality change and can be used to predict the corresponding quality deterioration resulting from postharvest sap handling and storage. Hence, it will boost the awareness of the need of clean conditions of tapping and collecting the sap to insure a high quality sap for high quality sugar.

Changes During the Heating Process of A. pinnata Sap Into Sugar

Previous studies on A. pinnata (Ho et al., 2006, 2007, 2008) have focused on compounds contained in the sap as well as compounds and volatile compounds during sugar processing. Those studies, so far, have not discussed about processing the sap into solid or granulated sugars.

The present study was designed to investigate the changes of temperature, total soluble solids and colour which occurred during the heating process of A. pinnata sap. Several colour quantifications, conducted on solid and granulated sugar, proved that the colour of both solid and granulated sugar was red-orange to yellow-orange, with granulated sugar being more yellow and colourful than solid sugar. The result provides important information to A. pinnata sugar farmers / industries to highlight the fact that heating must be regulated more carefully in the last period of the boiling process as the sap is heated much quicker and can easily get burnt. It also enhances our understanding about the colour change mechanisms which take place in processing of A. pinnata sap into sugar.

The Characterization of A. pinnata Sugar

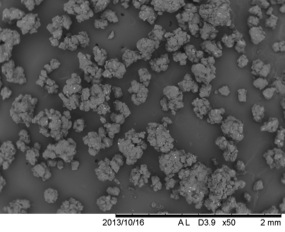

The globalisation of sources, regulatory agencies, consumer groups and the overall demand for safer foods drive the food industry to increase their focus on the analysis, authentication and characterisation of the raw materials, ingredients that are used in foods, and analyzsis and quality of the final food product (Rein 2012). Information about the characterisation including phyto nutrients of A. pinnata sugar is very limited, although the sugar is believed to be a healthy alternative sweetener and a more nutritious sugar than sugarcane (Tamunaidu et al. 2013). Our findings showed that A. pinnata sugar has around 90% of total sugar content and contains higher total phenolic content compared with white and refined sugar. The presence of high total phenolic content in A. pinnata sugar may be due to minimal chemical processing in the manufacture of the sugar which retains more polyphenols. Figure 5 presents an image of A. pinnata sugar by SEM.

Figure 5. SEM of granulated A. pinnata sugar

Conclusion

There is limited knowledge on how the underlying chemical and physical properties of A. pinnata sugar are affected during processing from sap into the final product. A. pinnata sap carries the potential for enhanced food quality and its changes during the process need to be quantified and described including measurement of physical, chemical and nutritional properties. Knowledge of internal processes is needed to improve existing techniques applied by indigenous people to enhance or minimise loss of product quality, and maintain product identity from the farm to the customer, in addition to providing safe food to customers.

Acknowledgments

The authors would like to acknowledge the Ministry of Education and Culture of Indonesia for financial support through a scholarship for the principal author.

References

Gonçalves, B, Silva, A P, Moutinho-Pereira, J, Bacelar, E, Rosa, E and Meyer, A S (2007) Effect of ripeness and postharvest storage on the evolution of colour and anthocyanins in cherries (Prunus avium L.). Food Chem. 103(3): 976-984.

Ho, CW, Aida, WMW, Maskat, MY and Osman, H (2006) Optimization of headspace solid phase microextraction (HS-SPME) for gas chromatography mass spectrometry (GC-MS) analysis of aroma compound in palm sugar (Arenga pinnata). J. Food Comp. Anal. 19(8): 822-830. doi: DOI 10.1016/j.jfca.2006.05.003

Ho, CW, Aida, WMW, Maskat, MY and Osman, H (2007) Changes in volatile compounds of palm sap (Arenga pinnata) during the heating process for production of palm sugar. Food Chem. 102(4): 1156-1162.

Ho, CW, Aida, WMW, Maskat, MY and Osman, H (2008). Effect of thermal processing of palm sap on the physico-chemical composition of traditional palm sugar. Pakistan J. Biol. Sci. 11(7): 989-995.

Lingle, S, Tew, T, Rukavina, H and Boykin, D (2013) Post-harvest changes in sweet sorghum II: pH, acidity, protein, starch, and mannitol. BioEnergy Res. 6(1): 178-187. doi: 10.1007/s12155-012-9248-5

Łysiak, G (2012) The base colour of fruit as an indicator of optimum harvest date for two apple cultivars (Malus domestica Borkh.). Folia Hort. 24(1): 81-89.

Marsigit, W (2005) Penggunaan bahan tambahan pada nira dan mutu gula aren yang dihasilkan di beberapa sentra produksi di Bengkulu. J. Penelitian UNIB, XI(1): 42-48.

Mogea, J, Seibert, B, and Smits, W (1991) Multipurpose palms - the sugar palm (Arenga pinnata (Wurmb) Merr). Agrofor. Syst. 13(2): 111-129.

Page, J K, Wulf, DM and Schwotzer, TR (2001) A survey of beef muscle color and pH. J. Anim. Sci. 79(3): 678-687.

Pathare, P, Opara, U and Al-Said, F-J (2013) Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess Technol. 6(1): 36-60.

Rein, A (2012) FTIR analysis provides rapid QA/QC and authentication of food ingredients prior to processing. Danbury, USA: Agilent Technologies Inc.; pp. 1-10.

Rindengan, B, Karouw, S and Pasang, P (2006. Pengaruh sabut kelapa terhadapk kualitas nira aren dan palm wine. J. Littri 12(4): 166-171.

Sahari, J, Sapuan, SM, Zainudin, ES and Maleque, MA (2012) Sugar palm tree: A versatile plant and novel source for biofibres, biomatrices, and biocomposites. Polym. Ren. Res. 3(2): 61-77.

Tamunaidu, P, Matsui, N, Okimori, Y and Saka, S (2013) Nipa (Nypa fruticans) sap as a potential feedstock for ethanol production. Biomass Bioenergy 52: 96-102.

Yagiz, Y, Balaban, MO, Kristinsson, HG, Welt, BA and Marshall, MR (2009) Comparison of Minolta colorimeter and machine vision system in measuring colour of irradiated Atlantic salmon. J. Sci. Food Agric. 89(4): 728-730.

Inneke Victor (from Institut Teknologi Minaesa [ITM], Manado, North Sulawesi, Indonesia) is a PhD student and Dr Valérie Orsat is a Professor at the Department of Bioresource Engineering, McGill University, Montreal, Quebec, Canada; e-mail: inneke.victor@mail.mcgill.ca .

This paper was awarded 1st Place in the IUFoST Food Safety Without Borders Graduate Paper Competition at the 17th IUFoST World Congress of Food Science and Technology held in Montreal, Quebec, Canada on 17-21 August 2014.

IUFoST Scientific Information Bulletin (SIB)

FOOD FRAUD PREVENTION